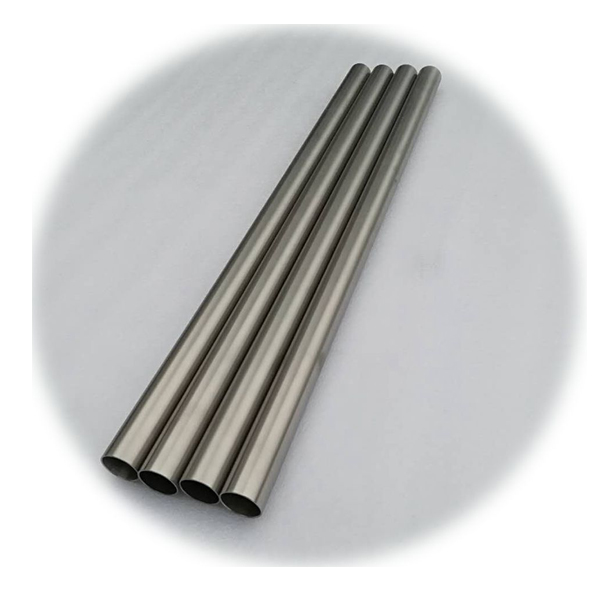

Model Number:

TA1

Application:

biomedical, aerospace,

Chimiro:

Round Tube

Material:

Tantalum

Dimensions:

O.D: 0.20 ~ 100mm Wall ukobvu: 0.05 ~ 10mm

Kemikari Kuumbwa:

Ta(99.95%min)

Density:

16.65g/cm3

Surface::

Bright

Nyika:

Annealing

Boiling Point:

5425

Melting Point:

3017

Supply Ability

Supply Ability

5000 Kilogram/Kilograms per Week

Packaging & Delivery

Packaging Details

Wooden Case

Port

Shanghai

Nguva Yekutungamira:

15

High Temperature Alloy Tantalum Capillary Tube 99.95%

Product Description

Ta&Ta-alloy (yakadai seTa-2.5W, Ta-10W, Ta-40Nb nezvimwewo) chubhu inogona kushandiswa kwepamusoro-tembiricha, kemikari uye indasitiri yeatomu nekuda kwekunyungudika kwayo, anti-corrosion, kutonhora kwekushanda uye humwe hunhu. .Inonyanya kushandiswa kugadzira reaction container panguva yechemical process , heat exchanger, pipeline, condensing apparatus, bayonet heater, spiral wire, U-tube, thermocouple plus kudzivirira chubhu uye liquid simbi mudziyo uye chubhu, ect.

Tantalum chubhu inonyanya kuiswa kugadzira tantalum mhinduro mudziyo, tantalum heat exchanger (shell & chubhu heat exchanger), tantalum pombi mutsetse (piping kana chiteshi), tantalum condenser, tantalum agitator, tantalum inotonhorera, tantalum boiler, tantalum bayonet heater, tantalum spiral ( helical) coil, U-tube heat exchanger kana "U" tube bundle heat exchanger panguva yechinhu chikamu chekudzikisa, kuvira zvakare, preheating uye kutonhora kwenitric acid, sulfuric acid, hydrochloric acid, formic acid uye musanganiswa wemaasidhi ane mamwe makemikari akawanda.

Tantalum chubhu inogona kuiswa mumatangi emvura emidziyo pamwe chete nemamwe magirazi ane mitsetse yemidziyo, tantalum thermo shoma uye tantalum thermocouple kuchengetedza sheaths, tantalum thermo tsime, tantalum emitter, tantalum sleeve, tantalum plasma spray inotarisisa uye tantalum tubular sputtering chinangwa.

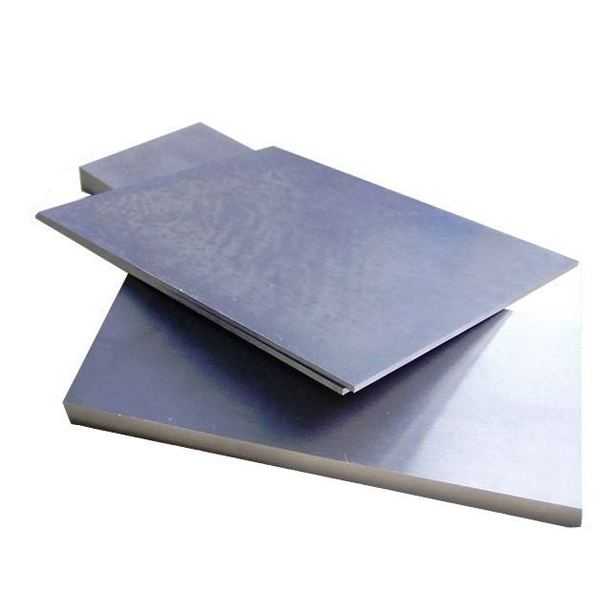

Product Zita | Tantalum Tube |

Material Composition | RO5200,Ta1, RO5252(Ta-2.5W),RO5255(Ta-10W) |

Kuchena | ≥99.95% |

Zvinotsanangurwa | O.D: 0.20~100mm Wall thickness: 0.05~10mm |

Kushivirira kwataigona kusangana nazvo: |

Out diameter: ±0.003mm Wall thickness: ±0.005mm |

Kemikari kuumbwa, Max |

Giredhi | Zvikamu zvikuru | Kusachena Kuumbwa, Max |

Ta | Nb | Fe | Si | Ni | W | Mo | Ti | O | C | H | N |

Ta1 (R05200) | chiyeuchidzo | 0.1 | 0.01 | 0.005 | 0.01 | 0.05 | 0.02 | 0.01 | 0.015 | 0.01 | 0.0015 | 0.01 |

Ta2(R05400) | chiyeuchidzo | 0.1 | 0.01 | 0.005 | 0.01 | 0.05 | 0.02 | 0.01 | 0.03 | 0.01 | 0.0015 | 0.01 |

Ta2.5W(R05252) | chiyeuchidzo | 0.5 | 0.1 | 0.005 | 0.01 | 2-3.5 | 0.02 | 0.01 | 0.015 | 0.01 | 0.0015 | 0.01 |

Ta10W(R05255) | chiyeuchidzo | 0.1 | 0.01 | 0.005 | 0.01 | 9-10 | 0.02 | 0.01 | 0.015 | 0.01 | 0.0015 | 0.01 |

TaNb35(R05240) | chiyeuchidzo | 35.0-42.0 | 0.01 | 0.005 | 0.01 | 0.05 | 0.02 | 0.01 | 0.02 | 0.01 | 0.0015 | 0.01 |

TaNb3 | chiyeuchidzo | <3.5 | 0.03 | 0.03 | 0.005 | 0.04 | 0.03 | 0.005 | 0.02 | 0.01 | 0.0015 | 0.01 |

TaNb20 | chiyeuchidzo | 17.0~23.0 | 0.03 | 0.03 | 0.005 | 0.04 | 0.03 | 0.005 | 0.02 | 0.01 | 0.0015 | 0.01 |

Zvinodiwa zvakakosha zvinobvumwa pane mutengesi uye mutengi |

Nei Tisarudze:

1. Unogona kuwana zvinhu zvakakwana maererano nezvaunoda pamutengo wakaderera.

2. Isu tinopawo Reworks, FOB, CFR, CIF, uye mitengo yekutumira pamusuwo kumasuo. Tinokupa zano kuti uite dhiri yekutumira iyo inove ine mari.

3. Zvishandiso zvatinopa zvinonyatso zivikanwa, kubva pagwaro rebvunzo retifiketi kusvika kune yekupedzisira dimensional statement. (Mishumo icharatidza pane zvinodiwa)

4. inovimbisa kupa mhinduro mukati memaawa makumi maviri nemana (kazhinji muawa imwe chete)

5. Unogona kuwana dzimwe nzira dzemasheya, kutakura zvigayo nekuderedza nguva yekugadzira.

6. Isu takazvipira zvizere kune vatengi vedu. Kana zvisingabviri kuzadzisa zvaunoda mushure mekuongorora zvese zvingasarudzwa, isu hatizokunyengedzi nekuita zvipikirwa zvenhema izvo zvinogadzira hukama hwakanaka hwevatengi.

Hunhu Simbiso (kusanganisira zvese Zvinoparadza uye Zvisiri Kuparadza)

1. Visual Dimension Test

2. Mechanical bvunzo senge tensile, Elongation uye kuderedzwa kwenzvimbo.

3. Kuongorora kwemigumisiro

4. Kemikari yekuongorora kuongorora

5. Kuoma bvunzo

6. Pitting kudzivirira bvunzo

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Roughness Testing

10. Metallography Experimental Test

Factory Tour

TAURA NESU

Bata munhu:Jennifer

Email :Info@Centuryalloy.Com

WhatsApp/Wechat : +86 18652029326