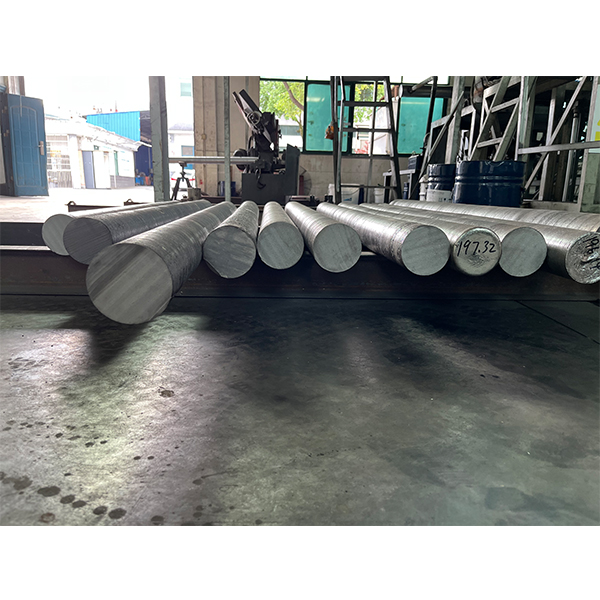

Metallury inoshandisa tantalum ingots

Mamiriro emuviri: Iine corrosion resistance uye inodzivirira tembiricha yakakwira, simba rakanaka, kusamira zvakanaka, plastiki, magadzirirwo akanakisa uye hukama hwakanaka nemuviri wemunhu.

Kunyanya kushandiswa: Inoshandiswa sechinhu chikuru chemidziyo yakasiyana-siyana yekugadzira tantalum, inoshandiswa zvakanyanya mupetroleum, makemikari, machira, zvemagetsi, maindasitiri ekugadzira uye ekugadzira zvinhu.

Kemikari ye tantalum ingots

Kemikari yakagadzirwa |

|

|

|

|

|

|

|

|

|

|

|

|

|

Giredhi | Fe | Si | Ni | W | Mo | Ti | Nb | O | C | H | N | Ta |

Ta1 | 0.005 | 0.005 | 0.005 | 0.005 | 0.002 | 0.002 | 0.005 | 0.02 | 0.004 | 0.002 | 0.005 | balance |

Ta2 | 0.005 | 0.005 | 0.005 | 0.005 | 0.002 | 0.002 | 0.1 | 0.03 | 0.01 | 0.002 | 0.01 | balance |

FTa1 | 0.005 | 0.005 | 0.005 | 0.005 | 0.002 | 0.002 | 0.005 | 0.02 | 0.003 | 0.002 | 0.005 | balance |

FTa2 | 0.01 | 0.03 | 0.01 | 0.005 | 0.002 | 0.002 | 0.1 | 0.035 | 0.003 | 0.002 | 0.01 | balance |

Remark | Ta1 uye Ta2 akagadzirwa ne ingot blanks, FTa1 neFTa2 akagadzirwa nembariro yakanyunguduka. |

Feature:

1.Good ductility;

2.Good plasticity;

3.Excellent acid-resistance;

4.High melting point, high boiling point;

5.Very duku coefficients yekuwedzera kwekushisa;

6.Kugona kwakanaka kwekutora uye kusunungura hydrogen.

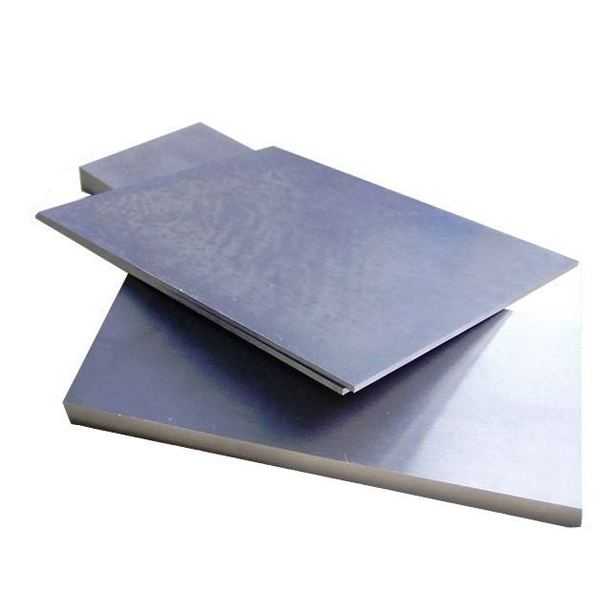

Giredhi, zviri mukati nemaapplication

Giredhi retantalum ndiro |

Giredhi | TTa-01 | TTa-02 | TTa-1 | TTa-2 |

Kusachena Kwemukati,%,max | O | 0.02 | 0.03 | 0.15 | 0.15 |

C | 0.005 | 0.006 | 0.015 | 0.02 |

N | 0.003 | 0.01 | 0.008 | 0.01 |

Fe | 0.005 | 0.01 | 0.005 | 0.01 |

Ni | 0.005 | 0.01 | 0.01 | 0.01 |

Cr | 0.005 | -- | 0.005 | 0.01 |

Nb | 0.005 | 0.1 | 0.01 | 0.02 |

W | 0.002 | 0.05 | 0.003 | 0.005 |

Mo | 0.001 | 0.02 | 0.003 | 0.005 |

Si | 0.002 | 0.025 | 0.003 | 0.015 |

Saizi (mm) | diameter(20-26)×(500-600) | (12-17)×(12-17)×(100-400) |

Density(g/cm3) | kuenzana kana kukwira kudarika 15.2 | -- |

Application | Kuti zvinhu zvigadziriswe | Kune superalloys uye electron-beam kunyunguduka |

|

Nei Tisarudze:

1. Unogona kuwana zvinhu zvakakwana maererano nezvaunoda pamutengo wakaderera.

2. Isu tinopawo Reworks, FOB, CFR, CIF, uye mitengo yekutumira pamusuwo kumasuo. Tinokupa zano kuti uite dhiri yekutumira iyo inove ine mari.

3. Zvishandiso zvatinopa zvinonyatso zivikanwa, kubva pagwaro rebvunzo retifiketi kusvika kune yekupedzisira dimensional statement. (Mishumo icharatidza pane zvinodiwa)

4. inovimbisa kupa mhinduro mukati memaawa makumi maviri nemana (kazhinji muawa imwe chete)

5. Unogona kuwana dzimwe nzira dzemasheya, kutakura zvigayo nekuderedza nguva yekugadzira.

6. Isu takazvipira zvizere kune vatengi vedu. Kana zvisingabviri kuzadzisa zvaunoda mushure mekuongorora zvese zvingasarudzwa, isu hatizokunyengedzi nekuita zvipikirwa zvenhema izvo zvinogadzira hukama hwakanaka hwevatengi.

Hunhu Simbiso (kusanganisira zvese Zvinoparadza uye Zvisiri Kuparadza)

1. Visual Dimension Test

2. Mechanical bvunzo senge tensile, Elongation uye kuderedzwa kwenzvimbo.

3. Kuongorora kwemigumisiro

4. Kemikari yekuongorora kuongorora

5. Kuoma bvunzo

6. Pitting kudzivirira bvunzo

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Roughness Testing

10. Metallography Experimental Test

Factory Tour

TAURA NESU

Bata munhu:Jennifer

Email :Info@Centuryalloy.Com

WhatsApp/Wechat : +86 18652029326