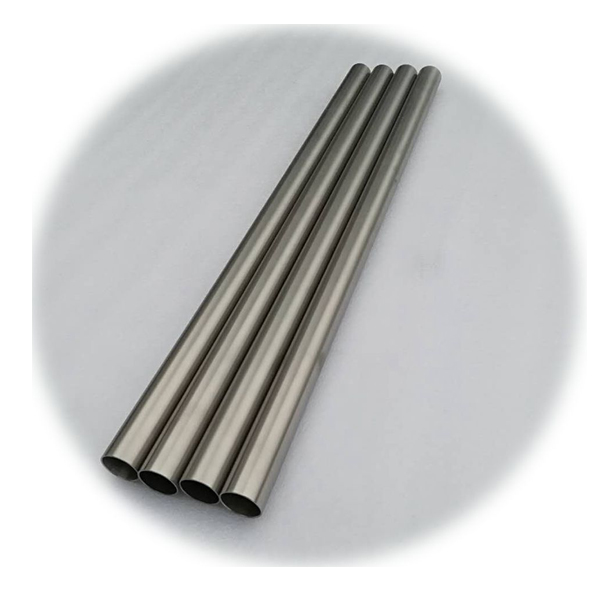

Model Number:

TA1

Application:

biomedical, aerospace,

Shape:

Round Tube

Material:

Tantalum

Dimensions:

O.D: 0.20~100mm Wall thickness: 0.05~10mm

Chemical Composition:

Ta(99.95%min)

Density:

16.65g/cm3

Surface::

Bright

State:

Annealling

Boiling Point:

5425

Melting Point:

3017

Supply Ability

Supply Ability

5000 Kilogram/Kilograms per Week

Packaging & Delivery

Packaging Details

Wooden Case

Port

Shanghai

Lead Time:

15

High Temperature Alloy Tantalum Capillary Tube 99.95%

Product Description

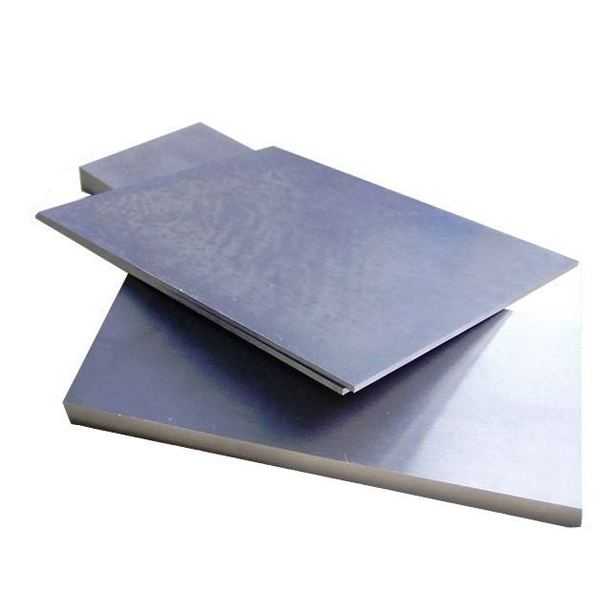

Ta&Ta-alloy (such as Ta-2.5W, Ta-10W, Ta-40Nb etc) tube can be used for high-temperature, chemical and atomic industry due to its high melting point, anti-corrosion, good cold workability and other characteristics.It is mainly used to produce reaction container during chemical process , heat exchanger, pipeline, condensing apparatus, bayonet heater, spiral wire, U-tube, thermocouple plus protecting tube and liquid metal container and tube,ect.

Tantalum tube is largely applied to produce tantalum response vessel, tantalum heat exchangers(shell & tube heat exchanger), tantalum pipe line(piping or channel), tantalum condenser, tantalum agitator, tantalum cooler, tantalum boiler, tantalum bayonet heater, tantalum spiral (helical) coil, U-tube heat exchanger or "U" tube bundle heat exchanger during the substance sector for condensing, re-boiling, preheating and cooling of nitric acid, sulfuric acid, hydrochloric acid, formic acid and combinations of those acids with a great deal of other chemicals.

Tantalum tube can be applied in fluid material tanks along with other glass-lined containers, tantalum thermo few and tantalum thermocouple safeguard sheaths, tantalum thermo well, tantalum emitter, tantalum sleeve, tantalum plasma spray focus on and tantalum tubular sputtering target.

Product Name | Tantalum Tube |

Material Composition | RO5200,Ta1, RO5252(Ta-2.5W),RO5255(Ta-10W) |

Purity | ≥99.95% |

Specifications | O.D: 0.20~100mm Wall thickness: 0.05~10mm |

The tolerance we could meet: |

Out diameter: ±0.003mm Wall thickness: ±0.005mm |

Chemical composition, Max |

Grade | Main components | Impurities Composition, Max |

Ta | Nb | Fe | Si | Ni | W | Mo | Ti | O | C | H | N |

Ta1 (R05200) | reminder | 0.1 | 0.01 | 0.005 | 0.01 | 0.05 | 0.02 | 0.01 | 0.015 | 0.01 | 0.0015 | 0.01 |

Ta2(R05400) | reminder | 0.1 | 0.01 | 0.005 | 0.01 | 0.05 | 0.02 | 0.01 | 0.03 | 0.01 | 0.0015 | 0.01 |

Ta2.5W(R05252) | reminder | 0.5 | 0.1 | 0.005 | 0.01 | 2-3.5 | 0.02 | 0.01 | 0.015 | 0.01 | 0.0015 | 0.01 |

Ta10W(R05255) | reminder | 0.1 | 0.01 | 0.005 | 0.01 | 9-10 | 0.02 | 0.01 | 0.015 | 0.01 | 0.0015 | 0.01 |

TaNb35(R05240) | reminder | 35.0-42.0 | 0.01 | 0.005 | 0.01 | 0.05 | 0.02 | 0.01 | 0.02 | 0.01 | 0.0015 | 0.01 |

TaNb3 | reminder | <3.5 | 0.03 | 0.03 | 0.005 | 0.04 | 0.03 | 0.005 | 0.02 | 0.01 | 0.0015 | 0.01 |

TaNb20 | reminder | 17.0~23.0 | 0.03 | 0.03 | 0.005 | 0.04 | 0.03 | 0.005 | 0.02 | 0.01 | 0.0015 | 0.01 |

Special requirements to be agreed upon seller and buyer |

Why Choose Us:

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. e guarantee to give a response within 24hours(usually in the same hour)

5. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

Quality Assurance(including both Destructive and Non-Destructive)

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Impact analysis

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Roughness Testing

10. Metallography Experimental Test

Factory Tour

CONTACT US

Contact person:Jennifer

Email : Info@Centuryalloy.Com

WhatsApp/Wechat : +86 18652029326