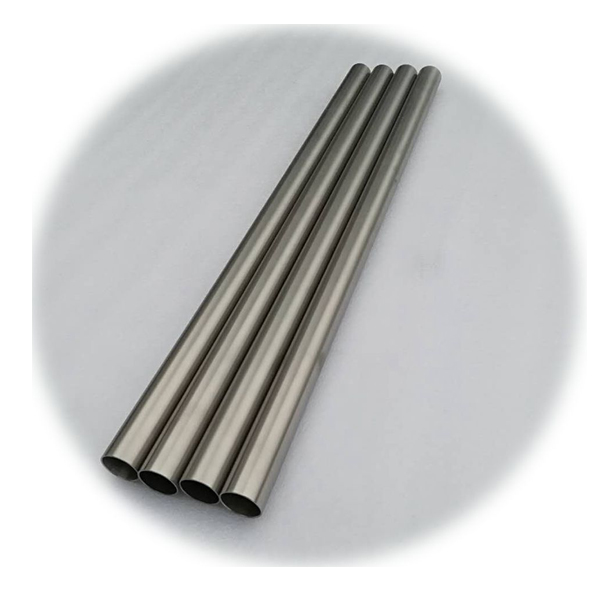

Qauv nab npawb:

TA1

Daim ntawv thov:

biomedical, aerospace, kev kho mob,

Cov duab:

Round Tube

Khoom siv:

Tantalum

Qhov Loj:

O.D: 0.20 ~ 100mm Phab ntsa thickness: 0.05 ~ 10mm

Tshuaj muaj pes tsawg leeg:

Ta(99.95%min)

Ceev:

16.65g/cm3

Nto::

Ci ntsa iab

Xeev:

Annealing

Boiling Point:

5425

Melting Point:

3017

Muaj peev xwm muab khoom

Muaj peev xwm muab khoom

5000 Kilogram / Kilograms ib lis piam

Ntim & Xa

Ntim Cov Lus Qhia

Ntoo Case

Chaw nres nkoj

Shanghai

Lub Sijhawm Lead:

15

Kub Kub Alloy Tantalum Capillary Tube 99.95%

Product Description

Ta&Ta-alloy (xws li Ta-2.5W, Ta-10W, Ta-40Nb thiab lwm yam) raj siv tau rau kev lag luam kub, tshuaj lom neeg thiab atomic kev lag luam vim nws qhov siab melting point, anti-corrosion, zoo txias ua hauj lwm thiab lwm yam ntxwv. .Nws yog tsuas yog siv los tsim cov tshuaj tiv thaiv thawv thaum cov txheej txheem tshuaj, tshav kub exchanger, pipeline, condensing apparatus, bayonet rhaub, kauv hlau, U-tube, thermocouple ntxiv tiv thaiv raj thiab kua hlau ntim thiab raj, ect.

Tantalum raj feem ntau siv los tsim tantalum teb lub nkoj, tantalum tshav kub exchangers (plhaub & raj kub exchanger), tantalum yeeb nkab kab (piping los yog channel), tantalum condenser, tantalum agitator, tantalum txias, tantalum boiler, tantalum bayonet rhaub, tantalum kauv ( helical) coil, U-tube kub exchanger los yog "U" tube bundle heat exchanger thaum lub sij hawm cov khoom sector rau condensing, re-boiling, preheating thiab txias ntawm nitric acid, sulfuric acid, hydrochloric acid, formic acid thiab ua ke ntawm cov acids nrog a ntau yam ntawm lwm yam tshuaj.

Tantalum tube tuaj yeem siv rau hauv cov khoom siv dej tso tsheb hlau luam nrog rau lwm lub khob iav, tantalum thermo ob peb thiab tantalum thermocouple tiv thaiv sheaths, tantalum thermo zoo, tantalum emitter, tantalum tes tsho, tantalum plasma spray tsom rau thiab tantalum tubular sputtering phiaj.

Khoom npe | Tantalum Tube |

Khoom siv | RO5200,Ta1, RO5252(Ta-2.5W),RO5255(Ta-10W) |

Purity | ≥99.95% |

Specifications | O.D: 0.20~100mm Wall thickness: 0.05~10mm |

Kev kam rau peb tuaj yeem ntsib: |

Out diameter: ±0.003mm Wall thickness: ±0.005mm |

Tshuaj muaj pes tsawg leeg, Max |

Qib | Cov ntsiab lus tseem ceeb | Impurities Composition, Max |

Ta | Nb | Fe | Si | Ni | W | Mo | Ti | O | C | H | N |

Ta1 (R05200) | ceeb toom | 0.1 | 0.01 | 0.005 | 0.01 | 0.05 | 0.02 | 0.01 | 0.015 | 0.01 | 0.0015 | 0.01 |

Ta2(R05400) | ceeb toom | 0.1 | 0.01 | 0.005 | 0.01 | 0.05 | 0.02 | 0.01 | 0.03 | 0.01 | 0.0015 | 0.01 |

Ta2.5W(R05252) | ceeb toom | 0.5 | 0.1 | 0.005 | 0.01 | 2-3.5 | 0.02 | 0.01 | 0.015 | 0.01 | 0.0015 | 0.01 |

Ta10W(R05255) | ceeb toom | 0.1 | 0.01 | 0.005 | 0.01 | 9-10 | 0.02 | 0.01 | 0.015 | 0.01 | 0.0015 | 0.01 |

TaNb35(R05240) | ceeb toom | 35.0-42.0 | 0.01 | 0.005 | 0.01 | 0.05 | 0.02 | 0.01 | 0.02 | 0.01 | 0.0015 | 0.01 |

TaNb3 | ceeb toom | <3.5 | 0.03 | 0.03 | 0.005 | 0.04 | 0.03 | 0.005 | 0.02 | 0.01 | 0.0015 | 0.01 |

TaNb20 | ceeb toom | 17.0~23.0 | 0.03 | 0.03 | 0.005 | 0.04 | 0.03 | 0.005 | 0.02 | 0.01 | 0.0015 | 0.01 |

Cov kev cai tshwj xeeb yuav tsum tau pom zoo raws li tus neeg muag khoom thiab tus neeg yuav khoom |

Vim li cas thiaj xaiv peb:

1. Koj tuaj yeem tau txais cov khoom zoo meej raws li qhov koj xav tau ntawm tus nqi tsawg kawg nkaus.

2. Peb kuj muab Reworks, FOB, CFR, CIF, thiab qhov rooj rau qhov rooj tus nqi xa khoom. Peb xav kom koj ua deal rau shipping uas yuav zoo heev.

3. Cov ntaub ntawv uas peb muab yog muaj tseeb tiag, txoj cai los ntawm raw cov ntaub ntawv xeem daim ntawv pov thawj mus rau qhov kawg dimensional nqe lus.

4. e lav muab cov lus teb tsis pub dhau 24 teev (feem ntau hauv tib lub sijhawm)

5. Koj tuaj yeem tau txais cov khoom lag luam, cov khoom xa tuaj nrog lub sijhawm tsim khoom tsawg.

6. Peb muaj siab rau peb cov neeg muas zaub. Yog tias nws yuav tsis tuaj yeem ua tau raws li koj cov kev xav tau tom qab kuaj xyuas tag nrho cov kev xaiv, peb yuav tsis ntxias koj los ntawm kev cog lus tsis tseeb uas yuav tsim kev sib raug zoo rau cov neeg siv khoom.

Quality Assurance (nrog rau kev puas tsuaj thiab tsis muaj kev puas tsuaj)

1. Visual Dimension Test

2. Kev tshuaj xyuas cov tshuab xws li tensile, Elongation thiab txo qhov chaw.

3. Kev soj ntsuam cuam tshuam

4. Tshuaj ntsuam xyuas

5. Kev sim hardness

6. Pitting tiv thaiv kuaj

7. Kev Xeem Penetrant

8. Intergranular Corrosion Test

9. Kev Ntsuas Roughness

10. Metallography Experimental Test

Lub Hoobkas ncig saib

Tiv tauj peb

Tus neeg tiv tauj:Jennifer

Email:Info@Centuryalloy.Com

WhatsApp / Wechat: +86 18652029326