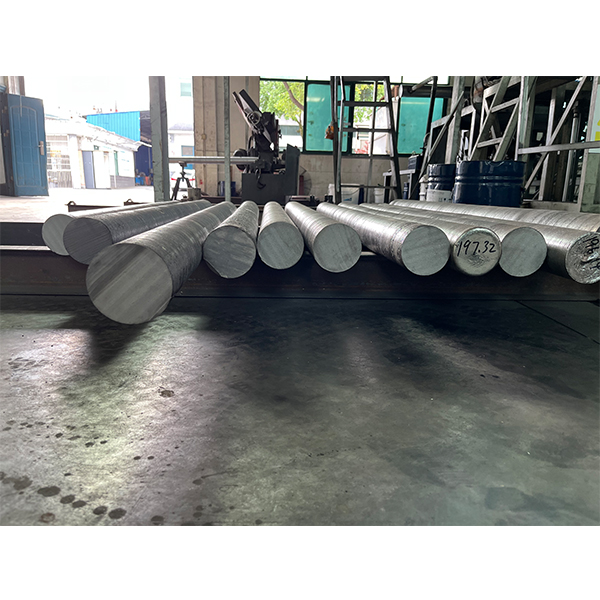

Metallury siv tantalum ingots

Lub cev muaj zog: Nws muaj kev tiv thaiv corrosion zoo thiab kub tsis kam, lub zog zoo, cuam tshuam tsis kam, plasticity, ua haujlwm zoo thiab muaj kev sib raug zoo nrog tib neeg lub cev.

Kev siv tseem ceeb: Siv los ua cov khoom siv tseem ceeb ntawm ntau yam khoom siv tantalum, dav siv hauv roj av, tshuaj, textile, electronics, manufacturing thiab khoom lag luam kev lag luam.

Tshuaj muaj pes tsawg leeg ntawm tantalum ingots

Tshuaj muaj pes tsawg leeg |

|

|

|

|

|

|

|

|

|

|

|

|

|

Qib | Fe | Si | Ni | W | Mo | Ti | Nb | O | C | H | N | Ta |

Ta1 | 0.005 | 0.005 | 0.005 | 0.005 | 0.002 | 0.002 | 0.005 | 0.02 | 0.004 | 0.002 | 0.005 | tshuav nyiaj li cas |

Ta2 | 0.005 | 0.005 | 0.005 | 0.005 | 0.002 | 0.002 | 0.1 | 0.03 | 0.01 | 0.002 | 0.01 | tshuav nyiaj li cas |

FTa1 | 0.005 | 0.005 | 0.005 | 0.005 | 0.002 | 0.002 | 0.005 | 0.02 | 0.003 | 0.002 | 0.005 | tshuav nyiaj li cas |

FTa2 | 0.01 | 0.03 | 0.01 | 0.005 | 0.002 | 0.002 | 0.1 | 0.035 | 0.003 | 0.002 | 0.01 | tshuav nyiaj li cas |

Lus ceeb toom | Ta1 thiab Ta2 yog ua los ntawm ingot blanks, Fta1 thiab FTa2 yog ua los ntawm ntsug melted tuav |

Feature:

1.Zoo ductility;

2.Plasticity zoo;

3.Excellent acid-ua hauj;

4.High melting point, siab boiling point;

5.Cov coefficients me me ntawm thermal expansion;

6.Lub peev xwm zoo ntawm absorbing thiab tso tawm hydrogen.

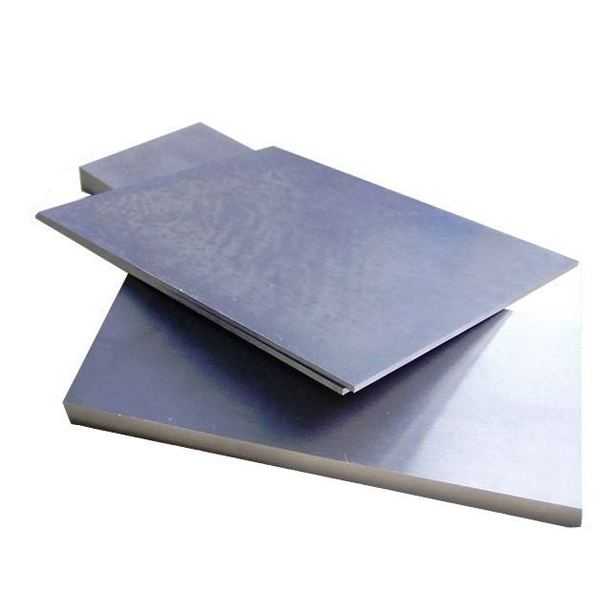

Qib, cov ntsiab lus thiab cov ntawv thov

Qib ntawm tantalum phaj |

Qib | TTa-01 | TTa-02 | TTa-1 | TTa-2 |

Cov ntsiab lus impurity,%, max | O | 0.02 | 0.03 | 0.15 | 0.15 |

C | 0.005 | 0.006 | 0.015 | 0.02 |

N | 0.003 | 0.01 | 0.008 | 0.01 |

Fe | 0.005 | 0.01 | 0.005 | 0.01 |

Ni | 0.005 | 0.01 | 0.01 | 0.01 |

Cr | 0.005 | -- | 0.005 | 0.01 |

Nb | 0.005 | 0.1 | 0.01 | 0.02 |

W | 0.002 | 0.05 | 0.003 | 0.005 |

Mo | 0.001 | 0.02 | 0.003 | 0.005 |

Si | 0.002 | 0.025 | 0.003 | 0.015 |

Loj (mm) | diameter(20-26)×(500-600) | (12-17)×(12-17)×(100-400) |

Density(g/cm3) | sib npaug lossis siab dua 15.2 | -- |

Daim ntawv thov | Rau cov khoom siv ua tiav | Rau superalloys thiab electron-beam melting |

|

Vim li cas thiaj xaiv peb:

1. Koj tuaj yeem tau txais cov khoom zoo meej raws li qhov koj xav tau ntawm tus nqi tsawg kawg nkaus.

2. Peb kuj muab Reworks, FOB, CFR, CIF, thiab qhov rooj rau qhov rooj tus nqi xa khoom. Peb xav kom koj ua deal rau shipping uas yuav zoo heev.

3. Cov ntaub ntawv uas peb muab yog muaj tseeb tiag, txoj cai los ntawm raw cov ntaub ntawv xeem daim ntawv pov thawj mus rau qhov kawg dimensional nqe lus.

4. e lav muab cov lus teb tsis pub dhau 24 teev (feem ntau hauv tib lub sijhawm)

5. Koj tuaj yeem tau txais cov khoom lag luam, cov khoom xa tuaj nrog lub sijhawm tsim khoom tsawg.

6. Peb muaj siab rau peb cov neeg muas zaub. Yog tias nws yuav tsis tuaj yeem ua tau raws li koj cov kev xav tau tom qab kuaj xyuas tag nrho cov kev xaiv, peb yuav tsis ntxias koj los ntawm kev cog lus tsis tseeb uas yuav tsim kev sib raug zoo rau cov neeg siv khoom.

Quality Assurance (nrog rau kev puas tsuaj thiab tsis muaj kev puas tsuaj)

1. Visual Dimension Test

2. Kev tshuaj xyuas cov tshuab xws li tensile, Elongation thiab txo qhov chaw.

3. Kev soj ntsuam cuam tshuam

4. Tshuaj ntsuam xyuas

5. Kev sim hardness

6. Pitting tiv thaiv kuaj

7. Kev Xeem Penetrant

8. Intergranular Corrosion Test

9. Kev Ntsuas Roughness

10. Metallography Experimental Test

Lub Hoobkas ncig saib

Tiv tauj peb

Tus neeg tiv tauj:Jennifer

Email:Info@Centuryalloy.Com

WhatsApp / Wechat: +86 18652029326