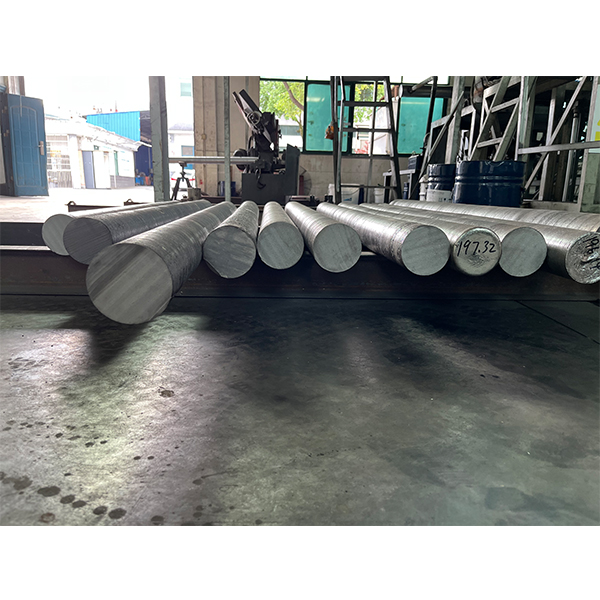

I-Metallury isebenzisa i-tantalum ingots

Izakhiwo zomzimba: Inokumelana nokugqwala okuhle nokumelana nezinga lokushisa eliphezulu, amandla amahle, ukumelana nokushayisana, ipulasitiki, izici ezinhle kakhulu zokucubungula nokuhlobana okuhle nomzimba womuntu.

Ukusetshenziswa okuyinhloko: Kusetshenziswa njengempahla yokusetshenziswa eyinhloko yezinto ezihlukahlukene zokucubungula i-tantalum, ezisetshenziswa kakhulu ku-petroleum, amakhemikhali, izindwangu, i-electronics, ukukhiqiza kanye nezimboni zokucubungula impahla.

Ukwakheka kwamakhemikhali kwama-tantalum ingots

Ukwakheka kwamakhemikhali |

|

|

|

|

|

|

|

|

|

|

|

|

|

Ibanga | Fe | Si | Ni | W | Mo | Ti | Nb | O | C | H | N | Ta |

Ta1 | 0.005 | 0.005 | 0.005 | 0.005 | 0.002 | 0.002 | 0.005 | 0.02 | 0.004 | 0.002 | 0.005 | ibhalansi |

Ta2 | 0.005 | 0.005 | 0.005 | 0.005 | 0.002 | 0.002 | 0.1 | 0.03 | 0.01 | 0.002 | 0.01 | ibhalansi |

FTa1 | 0.005 | 0.005 | 0.005 | 0.005 | 0.002 | 0.002 | 0.005 | 0.02 | 0.003 | 0.002 | 0.005 | ibhalansi |

FTa2 | 0.01 | 0.03 | 0.01 | 0.005 | 0.002 | 0.002 | 0.1 | 0.035 | 0.003 | 0.002 | 0.01 | ibhalansi |

Phawula | I-Ta1 ne-Ta2 zenziwe ngezikhala ze-ingot, i-FTa1 ne-FTa2 zenziwe ngamabha ancibilikisiwe aqondile. |

Isici:

1.I-ductility enhle;

2.Ipulasitiki enhle;

3.Ukumelana ne-asidi okuhle kakhulu;

4.Indawo yokuncibilika ephezulu, indawo yokubilisa ephezulu;

I-5.Ama-coefficients amancane kakhulu wokunweba okushisayo;

6.Ikhono elihle lokumunca nokukhipha i-hydrogen.

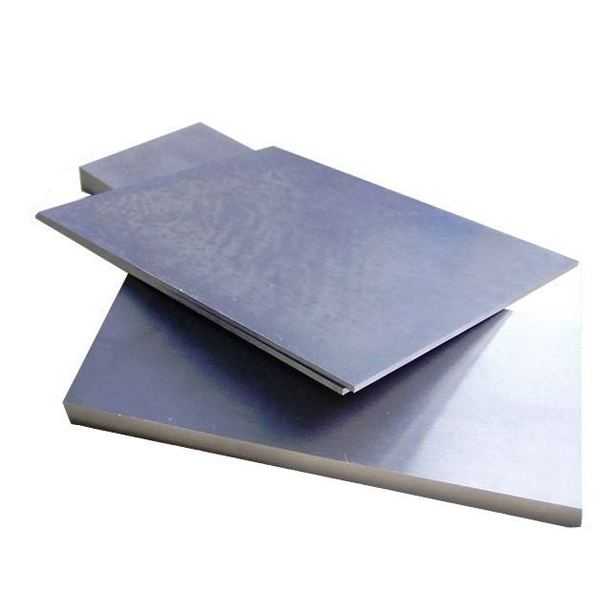

Ibanga, okuqukethwe nezinhlelo zokusebenza

Ibanga lepuleti le-tantalum |

Ibanga | TTa-01 | TTa-02 | TTa-1 | TTa-2 |

Okuqukethwe Ukungcola,%,ubukhulu | O | 0.02 | 0.03 | 0.15 | 0.15 |

C | 0.005 | 0.006 | 0.015 | 0.02 |

N | 0.003 | 0.01 | 0.008 | 0.01 |

Fe | 0.005 | 0.01 | 0.005 | 0.01 |

Ni | 0.005 | 0.01 | 0.01 | 0.01 |

Cr | 0.005 | -- | 0.005 | 0.01 |

Nb | 0.005 | 0.1 | 0.01 | 0.02 |

W | 0.002 | 0.05 | 0.003 | 0.005 |

Mo | 0.001 | 0.02 | 0.003 | 0.005 |

Si | 0.002 | 0.025 | 0.003 | 0.015 |

Usayizi (mm) | diameter(20-26)×(500-600) | (12-17)×(12-17)×(100-400) |

Density(g/cm3) | kulingana noma ngaphezulu kuno- 15.2 | -- |

Isicelo | Okokusebenza okuzocutshungulwa | Okwama-superalloys nokuncibilika kwe-electron-beam |

|

Kungani Usikhethe:

1. Ungathola impahla ephelele ngokuvumelana nemfuneko yakho okungenani inani elingenzeka.

2. Siphinde sinikeze ama-Reworks, i-FOB, i-CFR, i-CIF, nezintengo zokudiliva umnyango nomnyango. Siphakamisa ukuthi wenze isivumelwano sokuthunyelwa okuzokonga kakhulu.

3. Izinto esizihlinzekayo zingaqinisekiswa ngokuphelele, kusukela kusitifiketi sokuhlolwa kwempahla engavuthiwe kuya esitatimendeni sobukhulu bokugcina.(Imibiko izovela ngokwemfuneko)

4. isiqinisekiso sokunikeza impendulo phakathi namahora angu-24(imvamisa ngehora elifanayo)

5. Ungathola ezinye izindlela zesitoko, ukulethwa komshini ngokunciphisa isikhathi sokukhiqiza.

6. Sizinikele ngokugcwele kumakhasimende ethu. Uma kungeke kwenzeke ukuhlangabezana nezidingo zakho ngemva kokuhlola zonke izinketho, ngeke sikudukise ngokwenza izithembiso ezingamanga ezizodala ubudlelwano obuhle namakhasimende.

Ukuqinisekisa Ikhwalithi (okuhlanganisa kokubili Okubhubhisayo Nokungabhizi)

1. Visual Dimension Test

2. Ukuhlolwa kwemishini njengokushuba, Ukwelula kanye nokunciphisa indawo.

3. Ukuhlaziywa komthelela

4. Ukuhlaziywa kokuhlolwa kwamakhemikhali

5. Ukuhlolwa kokuqina

6. Ukuhlolwa kokuvikela umgodi

7. Ukuhlolwa Okungenele

8. I-Intergranular Corrosion Testing

9. Ukuhlolwa Kokuqina

10. Ukuhlolwa Kokuhlola Kwe-Metallography

I-Factory Tour

XHUMANA NATHI

Umuntu othintwayo:UJennifer

I-imeyili :Info@Centuryalloy.Com

I-WhatsApp/Wechat : +86 18652029326