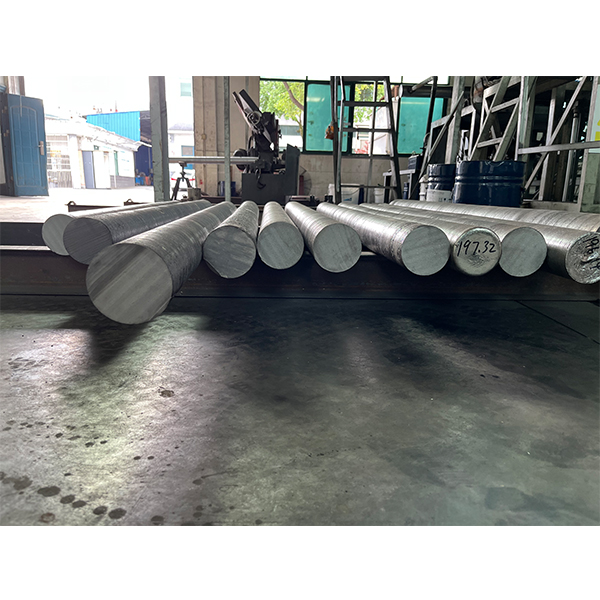

Metallury ntchito tantalum ingots

Kaonekedwe ka thupi: Ili ndi mphamvu yolimbana ndi dzimbiri komanso kutentha kwambiri, kulimba kwamphamvu, kusagwira ntchito, pulasitiki, kukonza bwino kwambiri komanso kugwirizana bwino ndi thupi la munthu.

Kagwiritsidwe ntchito kwambiri: Zomwe zimagwiritsidwa ntchito ngati zinthu zazikulu zopangira zinthu zosiyanasiyana za tantalum, zomwe zimagwiritsidwa ntchito kwambiri m'mafuta amafuta, mankhwala, nsalu, zamagetsi, zopanga ndi zopangira zinthu.

Mankhwala a tantalum ingots

Chemical zikuchokera |

|

|

|

|

|

|

|

|

|

|

|

|

|

Gulu | Fe | Si | Ni | W | Mo | Ti | Nb | O | C | H | N | Ta |

Ta1 | 0.005 | 0.005 | 0.005 | 0.005 | 0.002 | 0.002 | 0.005 | 0.02 | 0.004 | 0.002 | 0.005 | bwino |

Ta2 | 0.005 | 0.005 | 0.005 | 0.005 | 0.002 | 0.002 | 0.1 | 0.03 | 0.01 | 0.002 | 0.01 | bwino |

FTa1 | 0.005 | 0.005 | 0.005 | 0.005 | 0.002 | 0.002 | 0.005 | 0.02 | 0.003 | 0.002 | 0.005 | bwino |

FTa2 | 0.01 | 0.03 | 0.01 | 0.005 | 0.002 | 0.002 | 0.1 | 0.035 | 0.003 | 0.002 | 0.01 | bwino |

Ndemanga | Ta1 ndi Ta2 amapangidwa ndi mawu opanda kanthu, FTa1 ndi FTa2 amapangidwa ndi mipiringidzo yosungunuka. |

Mbali:

1.Good ductility;

2.Mapulasitiki abwino;

3.Kusamvana bwino kwa asidi;

4.Kusungunuka kwakukulu, malo otentha kwambiri;

5.Zochepa kwambiri za coefficients zowonjezera kutentha;

6.Kukhoza bwino kuyamwa ndi kutulutsa haidrojeni.

Gulu, zamkati ndi mapulogalamu

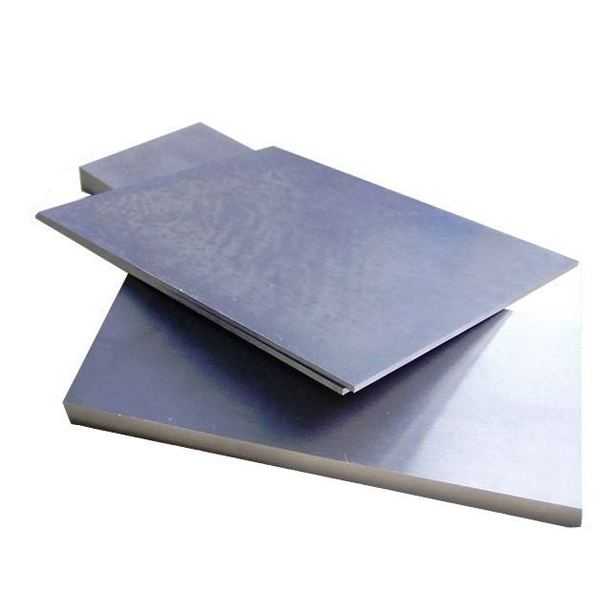

Gawo la mbale ya tantalum |

Gulu | TTa-01 | TTa-02 | TTa-1 | TTa-2 |

Zosayera,%,max | O | 0.02 | 0.03 | 0.15 | 0.15 |

C | 0.005 | 0.006 | 0.015 | 0.02 |

N | 0.003 | 0.01 | 0.008 | 0.01 |

Fe | 0.005 | 0.01 | 0.005 | 0.01 |

Ni | 0.005 | 0.01 | 0.01 | 0.01 |

Cr | 0.005 | -- | 0.005 | 0.01 |

Nb | 0.005 | 0.1 | 0.01 | 0.02 |

W | 0.002 | 0.05 | 0.003 | 0.005 |

Mo | 0.001 | 0.02 | 0.003 | 0.005 |

Si | 0.002 | 0.025 | 0.003 | 0.015 |

Kukula (mm) | diameter(20-26)×(500-600) | (12-17)×(12-17)×(100-400) |

Density(g/cm3) | ofanana kapena apamwamba kuposa 15.2 | -- |

Kugwiritsa ntchito | Kuti zipangizo kukonzedwa | Kwa superalloys ndi ma elekitironi-mtengo kusungunuka |

|

Chifukwa Chosankha Ife:

1. Mutha kupeza zinthu zabwino kwambiri malinga ndi zomwe mukufuna pamtengo wotsika kwambiri.

2. Timaperekanso Reworks, FOB, CFR, CIF, ndi mitengo yobweretsera khomo ndi khomo. Tikukulangizani kuti mugwiritse ntchito zotumiza zomwe zingakhale zotsika mtengo.

3. Zipangizo zomwe timapereka ndizotsimikizika kotheratu, kuyambira pa satifiketi yoyeserera mpaka pagawo lomaliza.

4. e chitsimikizo kupereka yankho mkati 24hours(nthawi zambiri mu ola lomwelo)

5. Mutha kupeza njira zina zogulitsira, zoperekera mphero ndikuchepetsa nthawi yopanga.

6. Ndife odzipereka kwathunthu kwa makasitomala athu. Ngati sizingatheke kukwaniritsa zomwe mukufuna mutapenda zonse zomwe mungasankhe, sitidzakusocheretsani popanga malonjezo abodza omwe angapangitse ubale wabwino ndi makasitomala.

Chitsimikizo cha Ubwino (kuphatikiza zonse Zowononga ndi Zosawononga)

1. Mayeso a Visual Dimension

2. Kuwunika kwamakina monga kukhazikika, kutalika ndi kuchepetsa dera.

3. Kusanthula zotsatira

4. Kusanthula kwa mankhwala

5. Mayeso olimba

6. Kuyesa chitetezo cha pitting

7. Mayeso Olowera

8. Intergranular Corrosion Testing

9. Mayeso Olimba

10. Metallography Experimental Test

Factory Tour

LUMIKIZANANI NAFE

Wolumikizana naye:Jennifer

Imelo :Info@Centuryalloy.Com

WhatsApp/Wechat : +86 18652029326